HDI Printed Circuit Boards in Next-Gen Automotive Tech

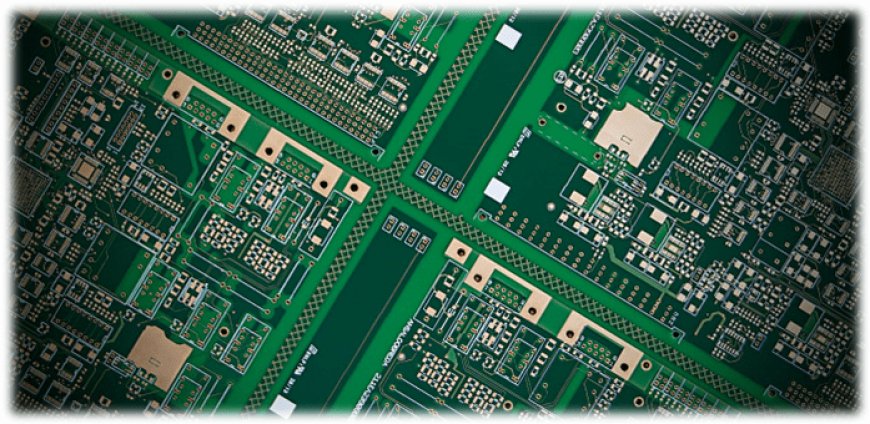

Offering enhanced functionality in a compact form factor, HDI Printed Circuit Boards are now playing an increasingly vital role in next-generation automotive technology.

In recent years, the automotive industry has undergone a radical transformation. From electric vehicles (EVs) to autonomous driving systems and connected car technologies, the demand for smarter, safer, and more efficient automobiles has never been greater. At the heart of this revolution lies a critical but often overlooked componentHDI Printed Circuit Boards (PCBs).

High-Density Interconnect (HDI) PCBs represent a major leap in electronic circuit design. Offering enhanced functionality in a compact form factor, HDI PCBs are now playing an increasingly vital role in next-generation automotive technology. Whether you're an engineer, industry professional, or just a curious tech enthusiast, this article explores the integral part HDI PCBs play in shaping the future of mobility.

What Are HDI Printed Circuit Boards?

Before diving into their automotive applications, its important to understand what HDI PCBs are. HDI stands for High-Density Interconnect. These circuit boards feature a higher wiring density per unit area compared to traditional PCBs. They are designed using advanced microvia technology, blind/buried vias, and sequential lamination processes.

This compact architecture allows more functions to be packed into smaller spaces, which makes HDI PCBs particularly well-suited for devices that demand miniaturization without compromising performancethink smartphones, medical devices, and now, next-generation vehicles.

To learn more about how these complex systems are designed and manufactured, check over here to explore detailed engineering breakdowns from leading industry sources.

The Role of HDI PCBs in Automotive Electronics

Modern vehicles are no longer just mechanical machines; they are sophisticated computers on wheels. From advanced driver-assistance systems (ADAS) to in-vehicle infotainment (IVI) and electric powertrains, electronics now account for nearly 40% of a vehicles total valueand that figure is only rising.

HDI Printed Circuit Boards are central to enabling this technological leap. Here's how:

1. Advanced Driver-Assistance Systems (ADAS)

ADAS features like lane departure warning, adaptive cruise control, and automated emergency braking rely on rapid data processing and real-time sensor integration. These systems require compact yet powerful PCBs to handle high-speed signal transmission and data computation.

HDI PCBs enable designers to fit multiple processors, sensors, and antennas into limited space without electromagnetic interference. As a result, vehicles can react more quickly to road conditions, improving safety for both drivers and pedestrians.

2. Electric and Hybrid Vehicles (EVs and HEVs)

As automakers push toward greener mobility, electric and hybrid vehicles are taking center stage. These vehicles rely on complex battery management systems (BMS), power electronics, and energy control modules, all of which demand high-performance circuitry.

HDI PCBs provide the necessary high-density interconnects to manage energy flow and ensure thermal stabilitykey factors in maintaining battery efficiency and safety. If youre curious about the cutting-edge applications of HDI in EV platforms, you can Find Out More through technical whitepapers from manufacturers and Tier 1 suppliers.

3. In-Vehicle Infotainment and Connectivity

The automotive cockpit has evolved dramatically. Touchscreens, voice assistants, 5G connectivity, and real-time navigation are now standard features in many new models. These systems require fast data transmission, minimal latency, and high reliabilityall of which are made possible by HDI PCB designs.

HDI Printed Circuit Boards offer enhanced signal integrity and allow for the integration of multiple functions onto a single board, resulting in sleeker designs and improved user experience. To see how automakers are using this technology in their latest models, go right here for industry trend reports and case studies.

4. Autonomous Driving and AI Integration

Perhaps the most futuristic application of HDI PCBs is in autonomous driving. These vehicles depend on massive data from LIDAR, RADAR, cameras, and onboard AI systems. The amount of information being processed in real time is staggering.

HDI PCBs help manage this data flow efficiently, enabling real-time processing with reduced latency. Their compact size also allows more components to be placed closer together, which minimizes signal loss and increases performanceessential for decision-making in autonomous vehicles.

Advantages of HDI PCBs in Automotive Design

Beyond their role in specific applications, HDI PCBs offer several advantages that make them an ideal choice for the automotive sector:

- Size and Weight Reduction: Essential for fuel efficiency and space management in electric and compact vehicles.

- Enhanced Reliability: Less prone to failure due to fewer interconnections and shorter signal paths.

- High-Speed Performance: Supports high-frequency signals required in ADAS and infotainment systems.

- Thermal Management: Effective heat dissipation, crucial in power electronics and EVs.

- Design Flexibility: Enables multi-layer boards, facilitating integration of various modules on a single PCB.

These benefits translate into more robust and versatile automotive electronics capable of meeting future demands.

Challenges and Future Outlook

Despite their advantages, integrating HDI PCBs into automotive systems is not without challenges. Cost remains a key barrier, as HDI manufacturing processes are more complex than traditional PCB production. Additionally, ensuring durability under extreme temperature fluctuations and vibrations is critical.

However, ongoing advancements in materials science, automation, and fabrication techniques are steadily reducing these hurdles. As technology evolves, HDI PCBs are expected to become even more affordable and efficient.

Looking ahead, we can anticipate the emergence of flexible HDI PCBs and multi-functional boards that further redefine automotive design possibilities. For industry professionals looking to stay ahead of the curve, its wise to Find Out More by attending trade shows and subscribing to automotive electronics journals.

Final Thoughts

As the automotive industry continues to innovate, HDI Printed Circuit Boards will remain a cornerstone of progress. Their ability to meet the demands of miniaturization, performance, and reliability make them indispensable in next-gen vehicle technology.

Whether you're working on electric drivetrains, autonomous navigation systems, or simply exploring the future of smart mobility, understanding the capabilities of HDI PCBs can give you a crucial edge.

To dive deeper into specific use cases or explore HDI PCB manufacturers leading the charge, check over here for expert analysis and product reviews. And if you want to get hands-on insights, dont hesitate to go right here to connect with suppliers, engineers, and innovators who are shaping the automotive tech landscape.