The Role of Document Control in ISO 13485 and FDA 21 CFR Part 11 Compliance

Discover the critical role of document control in ensuring compliance with ISO 13485 and FDA 21 CFR Part 11. Learn how effective document management systems support traceability, maintain version control, and ensure regulatory readiness, enabling medical device manufacturers to meet both quality standards and regulatory requirements.

Strengthening Compliance through Medical Device Document Control Software Systems

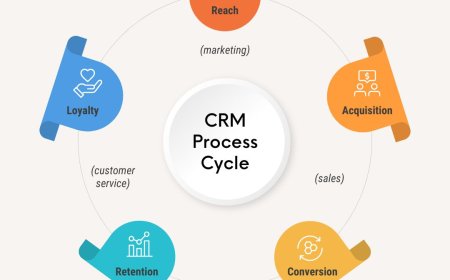

In todays regulated life sciences landscape, the use of Medical Device Document Control Software Systems is no longer a matter of choice but a strategic imperative. With ISO 13485 and FDA 21 CFR Part 11 requiring stringent documentation protocols, manufacturers must ensure accuracy, consistency, and traceability across all product and process documentation. These regulatory frameworks emphasize the critical role of documentation in safeguarding patient health and product reliability. The integration of document management software into a robust quality management system (QMS) addresses these demands by providing a compliant, secure, and efficient infrastructure for managing the entire document lifecycle.

Unifying Document Control with ISO 13485-Compliant Quality Management Systems

ISO 13485 mandates comprehensive documentation controls throughout the medical device product lifecycle, from design to distribution. Medical device document control software systems provide a centralized platform that ensures all documents are stored, version-controlled, and accessible based on user permissions. A unified QMS with embedded document management functionality enables seamless traceability, rapid retrieval, and real-time collaboration, which are essential for audits and inspections.

These systems help manufacturers implement document workflows that enforce review, approval, and training steps according to ISO 13485 standards. They also reduce the risk of human error and outdated information being used in manufacturing or quality processes, ultimately enhancing quality management performance and ensuring continuous compliance.

Ensuring Data Integrity and Traceability Under FDA 21 CFR Part 11

FDA 21 CFR Part 11 focuses on the security, integrity, and authenticity of electronic records and signatures. Medical device document control software systems ensure that all documentation processes meet these requirements by capturing audit trails, enforcing e-signature controls, and securing access rights.

Such systems are validated to operate under FDA guidelines, ensuring that data cannot be altered without authorization. By incorporating robust security protocols and maintaining a chain of custody for documents, they help manufacturers demonstrate full compliance during regulatory audits. Document management systems aligned with FDA expectations are vital in preventing compliance gaps and avoiding costly enforcement actions.

Closing the Loop Between Document Management Software and CAPA, Change Control, and Risk Management

To achieve holistic compliance, document management software must be integrated with critical QMS processes like CAPA, change control, and risk assessments. This closed-loop approach ensures that when a quality issue is identified, related documentsincluding procedures, specifications, or training materialsare automatically reviewed and updated.

Medical device document control software systems that support this level of integration drive accountability and accelerate issue resolution. They maintain alignment between operational updates and documented requirements, which is a core expectation of ISO 13485 and FDA compliance programs. It also ensures that risk controls are correctly documented and traceable, reducing liability and improving overall product safety.

Driving Operational Excellence with Quality Management System Integration

A document control strategy that is disconnected from other QMS functions poses significant challenges for maintaining compliance and audit readiness. Document management software embedded within a comprehensive QMS allows for consistent implementation of quality policies across all business units and product lines.

With real-time data synchronization between document control and quality events, organizations can align decision-making with accurate, up-to-date information. Whether its training records, validation reports, or SOP revisions, integrated document control ensures that every process is supported by current, compliant documentation. This drives higher levels of operational efficiency and supports strategic objectives for global market access.

Enabling Faster Audits and Regulatory Submissions with Document Management System Capabilities

Medical device companies are increasingly under pressure to respond to FDA inspections, notified body audits, and health authority inquiries across jurisdictions. An effective document management system significantly reduces the burden by providing rapid access to required documents through intelligent search, role-based access, and automated version histories.

Medical device document control software systems offer metadata tagging, customizable folder structures, and full audit trails that simplify the compilation of regulatory submissions. These capabilities are vital for demonstrating ongoing compliance with both ISO 13485 and 21 CFR Part 11, enabling organizations to accelerate their time-to-market and maintain a competitive edge.

Training and Change Implementation Through Document Management Software

Regulatory agencies expect documented evidence that employees are trained on the latest procedures and product specifications. Medical device document control software systems allow for the automatic distribution of new or revised documents to relevant personnel and track training acknowledgments.

When integrated with change control workflows, the system ensures that changes to controlled documents trigger training updates, minimizing the risk of non-compliance. This training linkage is critical in demonstrating regulatory adherence and continuous improvement, a cornerstone of both ISO 13485 and FDA compliance philosophies.

Managing Global Documentation Requirements in Multi-Site Operations

For organizations operating across multiple geographies, document control becomes even more complex. Different regulatory bodies may require region-specific documentation formats, languages, or content. A centralized, validated document management system ensures that all locations adhere to a consistent global standard while allowing for local customization where necessary.

Medical device document control software systems streamline document creation, distribution, and localization processes across regions. This supports harmonized compliance with ISO 13485 and FDA regulations, while also preparing organizations for future requirements such as EU MDR, TGA in Australia, or Health Canada standards.

Enhancing Visibility and Accountability Through Real-Time Document Tracking

One of the key benefits of using advanced document control systems is real-time visibility into the document lifecycle. Organizations can track who accessed, edited, reviewed, or approved documents, along with timestamps and digital signatures. This visibility is crucial in managing document-related risks and ensuring that all users are working with the most current version.

When tied to QMS metrics, this visibility also enables proactive monitoring of documentation healthsuch as overdue reviews or training completion statusand supports better decision-making. By incorporating dashboard analytics, organizations can continuously assess the effectiveness of their document control processes and take corrective actions as needed.

Conclusion: Why ComplianceQuest is Essential for Business in 2025

As the regulatory landscape for medical devices continues to evolve, manufacturers must embrace digital solutions that support both compliance and operational excellence. ComplianceQuest delivers a unified platform where document management software, quality management system functions, and regulatory workflows converge into a single source of truth.

With ComplianceQuest, organizations benefit from medical device document control software systems that are purpose-built for ISO 13485 and FDA 21 CFR Part 11 requirements. The platform supports integration across change control, CAPA, training, audits, and risk managementensuring comprehensive coverage of compliance obligations. In 2025, where speed-to-market, audit-readiness, and product quality are non-negotiable, ComplianceQuest enables manufacturers to meet regulatory expectations with confidence and agility.

By investing in a modern QMS with robust document control capabilities, companies position themselves to scale operations, mitigate compliance risks, and deliver safer medical devices to global markets.